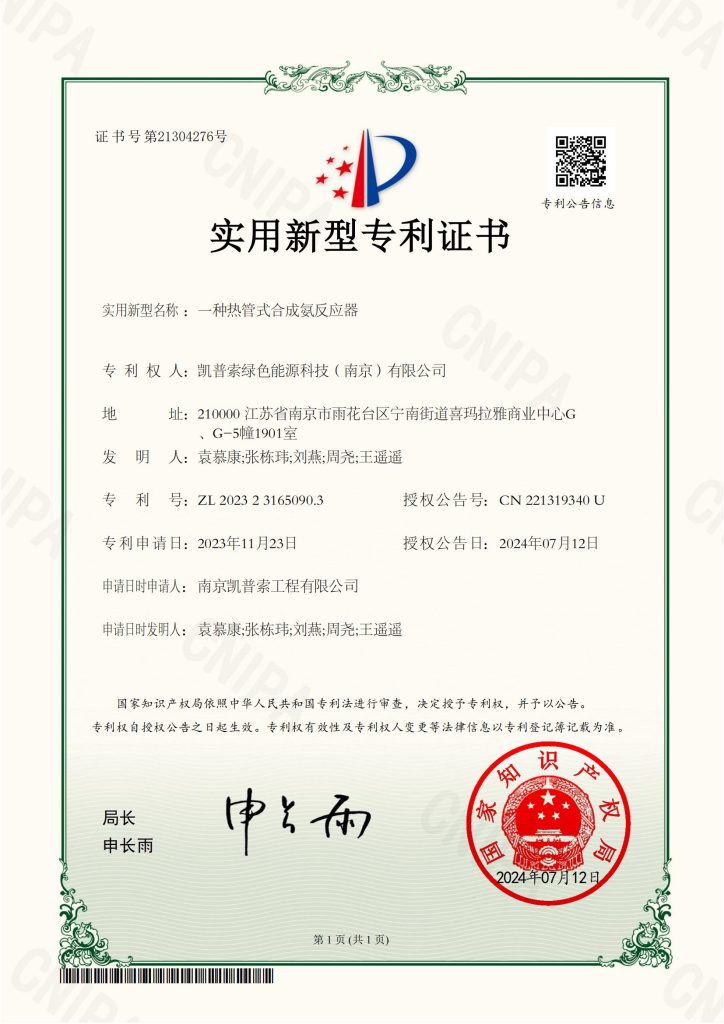

Recently, KAPSOM has been granted a utility model patent for its “Heat Pipe-Based Ammonia Synthesis Reactor” by the National Intellectual Property Administration, with patent number ZL 2023 2 3165090.3. This marks another significant acknowledgment of our company’s R&D capabilities and represents a major milestone in our journey of technological innovation.

Ammonia, a critical chemical raw material, is widely used in the production of fertilizers, refrigerants, explosives, and various chemicals. As a cornerstone of the chemical industry, ammonia synthesis is characterized by high production volumes and energy consumption. The principle behind ammonia synthesis involves maintaining the ammonia synthesis reactor under high-temperature and high-pressure conditions, facilitating the reaction between nitrogen and hydrogen to produce ammonia, catalyzed by a specific catalyst.

Currently, most ammonia synthesis reactors on the market are vertical cylindrical units, typically equipped with multiple horizontal catalyst layers. The reaction gases flow from top to bottom through these various catalyst layers, enabling reactions at different catalyst layer temperatures. To ensure optimal temperature conditions for the catalyst layers, heat exchange structures are employed. Traditionally, multiple heat exchange tubes are used to transfer heat away from the catalyst layers. However, this conventional heat exchange structure suffers from cold tube effects, leading to decreased reactor efficiency and uneven temperature distribution in the catalyst layers, resulting in imprecise temperature control and lower reaction efficiency.

Addressing these limitations, we have innovated a Heat Pipe-Based Ammonia Synthesis Reactor. By partitioning the cylindrical reactor into heat exchange and reaction chambers with a separator plate, this design leverages the high thermal conductivity of heat pipes to achieve uniform temperature control and precise adjustment of the catalyst layers, significantly enhancing reaction efficiency. The multiple catalyst layers inside the reactor are evenly distributed and staggered with heat pipes, allowing the reaction gases to fully interact and efficiently produce ammonia. The heat generated during the reaction is transferred through the heat pipes to the heat exchange chamber and then carried away by the heat exchange gas, ensuring a stable and efficient reaction process.

We recognize the importance of intellectual property protection in safeguarding our legal rights and enhancing brand value. Moving forward, KAPSOM is committed to advancing its technological innovation strategy, deeply exploring product optimization and innovation potentials, accelerating the conversion of technological achievements into practical applications, and actively exploring commercialization pathways. These efforts will transform innovative results into a powerful engine driving our continued and healthy development.

For more information about KAPSOM and its initiatives, please contact dongling@kapsom.com.