KAPSOM’s green urea plant solution prioritizes sustainability with features such as low-carbon environmental protection and high CO2 conversion efficiency of at least 60%.

KAPSOM’s green urea equipment integrates advanced technologies to minimize carbon emissions during production.By employing innovative processes and materials, the equipment reduces its environmental footprint, aligning with sustainability goals.

KAPSOM’s equipment boasts a CO2 conversion efficiency of at least 60%, signifying its effectiveness in reducing greenhouse gas emissions.Through optimized processes and engineering, the equipment maximizes the utilization of CO2, thereby enhancing overall efficiency and sustainability.

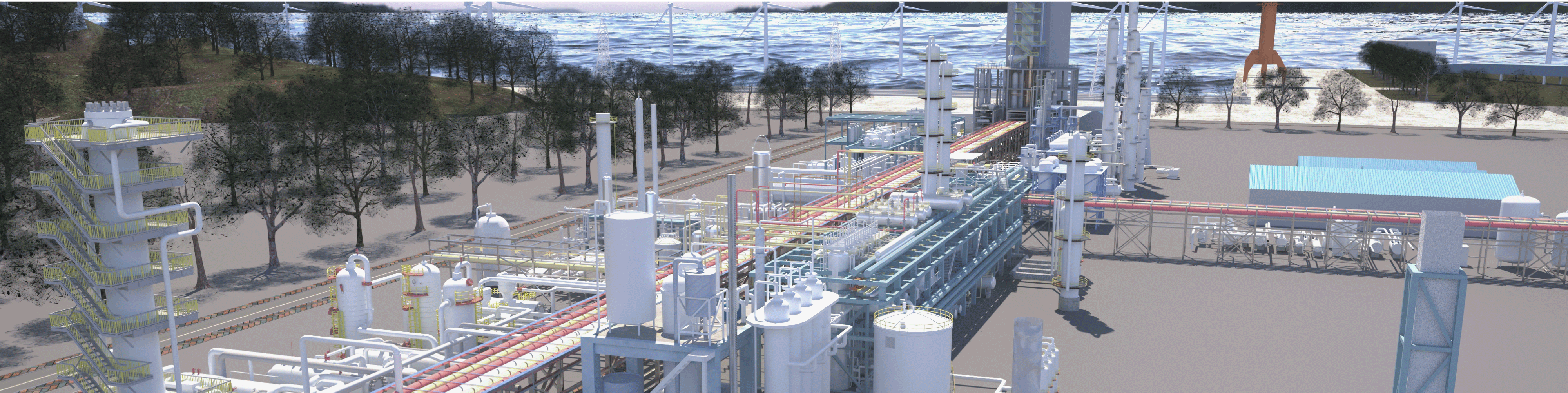

KAPSOM manufactures its green urea equipment in ASME-certified factories, ensuring compliance with stringent industry standards. By adhering to ASME standards, KAPSOM demonstrates its commitment to producing environmentally sustainable solutions without compromising product integrity.

KAPSOM’s green urea plant is designed to be highly customizable, allowing it to meet the specific needs and preferences of users. This adaptability ensures that the equipment can be tailored to various small-scale production requirements, ensuring optimal performance and efficiency.

In small-scale production settings, green urea production adopts a decentralized model. This decentralized approach facilitates more agile and adaptable operations, making it easier to adjust to different production capacities and scenarios commonly found in smaller-scale setups.

Both KAPSOM’s green ammonia and green urea production methods are engineered to seamlessly adapt to diverse production capacities. Whether it’s a small-scale industrial operation or a decentralized setup, these solutions efficiently accommodate different production needs without compromising efficiency.

This tailor-made approach promotes sustainable growth by optimizing resource utilization, maximizing the adaptation of front-end green energy, and reducing the inability of renewable energy to be integrated into the grid. This contributes to a more environmentally friendly and economically feasible large-scale production process.

Green urea is a renewable, emission-free urea product, derived from green ammonia, and it finds widespread applications in the agricultural sector. Green urea holds the potential to achieve decarbonization in agriculture, reduce greenhouse gas emissions, and address food security challenges.

As raw materials for the production of urea-formaldehyde resin and melamine, to provide energy for the hydrolysis process of forming ammonia, as compound fertilizers and blends Composting ingredients, etc. In 2011, KAPSOM assisted a large chemical fertilizer company in Henan Province to build a urea plant, and the plant was completed and put into operation in 2011.

In 2020, the trial run of a project with an annual production capacity of 400,000 tons of synthetic ammonia and 600,000 tons of urea was successful. The project utilized GE coal-water slurry gasification, isothermal transformation, and improved carbon dioxide-stripping urea technology. This further promoted capacity expansion and enhanced cost efficiency.

Urea stands as the primary solid nitrogen fertilizer worldwide, offering a practical solution to bolster crop yields and profitability. However, the conventional urea (CH4N2O) production process generates a staggering 12.5 million tons of carbon dioxide (CO2) annually, rendering it one of the largest contributors to CO2 emissions within the chemical industry. Despite its paramount role in agriculture, urea also boasts significant applications in industry and healthcare.

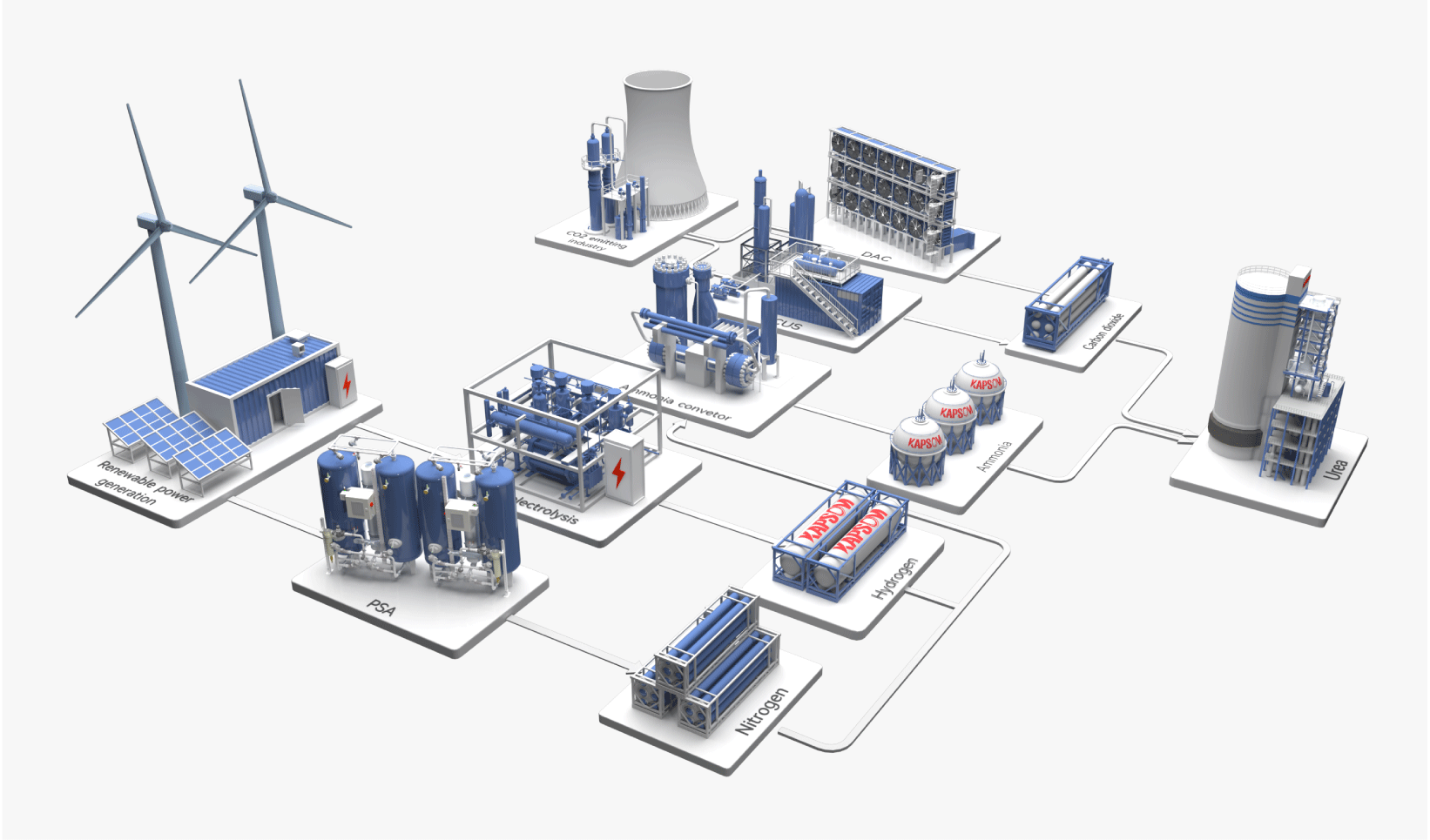

Green urea uses carbon capture technology to capture and store carbon dioxide, electrolyze water to produce carbon-free hydrogen, and then use the generated hydrogen to react with nitrogen (usually extracted from the air) to produce green ammonia. Green ammonia and carbon dioxide (CO2) synthesize green urea and water.

By adopting this innovative process, green urea effectively mitigates CO2 emissions, representing a pivotal step towards decarbonizing agriculture. This shift not only aligns with sustainability goals but also signifies a progressive leap towards environmentally responsible farming practices.

The production process of traditional urea (which accounts for more than 70% of global fertilizer use) emits carbon dioxide, a greenhouse gas and a major contributor to climate change. Climate change also leads to earlier crop development, shorter growth cycles, reduced yields, and lower quality. It results in increased climate variability, leading to higher instability in agricultural production.

As global temperatures and sea levels rise, there are more heatwaves, droughts, floods, hurricanes, and wildfires. Such conditions make it difficult for farmers to grow crops, and hungry people struggle to access food.

In general, for every 1°C increase in temperature, air humidity can increase by about 7%. Therefore, climate change may lead to increased frequency, intensity, and quantity of heavy rainfall in certain regions, subsequently increasing the rate of soil erosion.

Many wild relatives of crops that are essential for long-term food security lack effective protection. Reduced diversity will diminish agriculture’s resilience to future climate change, pests, and pathogens.

Green urea is widely used in the field of agriculture. As a neutral fertilizer, green urea is suitable for various soils and plants. It is easy to store, convenient to use, and has a minimal impact on the soil. It is currently one of the most widely used chemical nitrogen fertilizers.

According to United Nations projections, the world’s population is expected to reach 8.5 billion by 2030 and 9.7 billion by 2050. Estimates indicate that to feed the global population by 2050, total food production will need to increase by nearly 60% compared to current levels.

Green urea is a derivative of green ammonia, and it is produced by reacting green ammonia with CO2 from urea plants to create green urea products without carbon emissions. It not only reduces greenhouse gas carbon emissions but also serves as a raw material for various industrial applications, facilitating carbon neutrality in automobile emissions and playing a fundamental role in ensuring global food security.

In 2022, the global urea market reached $50.9 billion, and it is projected to reach $57 billion by 2028. The continuous expansion of the global population has led to a sustained increase in the demand for fertilizers. Green urea, apart from being used as a feed supplement and fertilizer, is also employed as a raw material for pharmaceuticals and plastics production. In the context of global decarbonization, urea can also be utilized in the automotive industry to convert nitrogen oxides from vehicle emissions into harmless nitrogen and water, potentially further supporting market growth. The green urea market holds significant potential.

In the field of dermatology, certain medications containing urea are used to increase skin moisture.

Green urea is a high-concentration nitrogen fertilizer that does not leave any harmful residues in the soil, and long-term application has no adverse effects.

Green urea can serve as a major production raw material for various products such as melamine, urea-formaldehyde resins, monosodium glutamate, plastics, and more.

Automotive urea is used for treating the exhaust emissions of diesel engines, internal combustion engines, and thermal power plants.