The Smart system has obvious features such as Smart screen Remote HMI and Multi-camera surveillance. By

combining these three components, the Smart system can greatly improve the management efficiency of green

ammonia plant, reduce on-site workload, and eliminate data isolation of green ammonia plant. The detailed

explanation is as follows.

The remote HMI contains on-site Smart screen content and collects safety, process, equipment, consumption,and product information within the green ammonia plant, breaking the data isolation of various systems in the plant and achieving effective integration of safety, production, management, and operation data of the green ammonia plant. In addition, the remote HMI also has functions such as real-time PID monitoring, operation data analysis and playback, trend analysis, data query, alarm management, message push, and comprehensive reporting, enabling the green ammonia plant to monitor and operate anytime and anywhere.

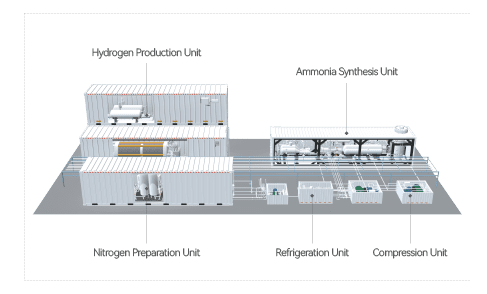

| Unit | Length (m) | Width (m) | Height (m) |

|---|---|---|---|

| Hydrogen Preparation Unit | 13 | 6 | 5.5 |

| Nitrogen Preparation Unit | 10 | 6 | 2.9 |

| Compression Unit | 10 | 5 | 1.7 |

| Ammonia Synthesis Unit | 12 | 2.5 | 2.8 |

| Refrigeration Unit | 6 | 2.5 | 2.5 |

| MAIN PARAMETERS OF GA-2,000 (2,000TPA) | |||||

|---|---|---|---|---|---|

| Unit | Hydrogen Preparation Unit | Nitrogen Preparation Unit | Compression Unit | Ammonia Synthesis Unit | Refrigeration Unit |

| Cooling Water (T/h) | 80 | 10 | 5 | 6 | 20 |

| Electricity Consumption (kWh/h) | 2,500 | 60 | 55 | 37.5 | 85 |

| Floor Area (m²) | 78 | 60 | 50 | 30 | 15 |

*Volume ratio of the layout:0.75| Demineralized water consumption of hydrogen production unit: 0.5T/h

*All data are only for theoretical reference, and the specific data shall be calculated according to the actual project background.

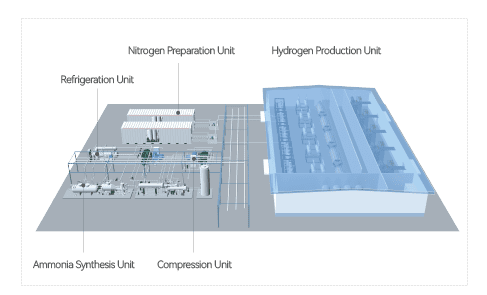

| Unit | Length (m) | Width (m) | Height (m) |

|---|---|---|---|

| Hydrogen Preparation Unit | 60 | 28 | 10 |

| Nitrogen Preparation Unit | 15 | 7 | 4 |

| Compression Unit | 14 | 10 | 2.5 |

| Ammonia Synthesis Unit | 12 | 7 | 4.5 |

| Refrigeration Unit | 10 | 3.5 | 3 |

| MAIN PARAMETERS OF GA-20,000 (20,000TPA) | |||||

|---|---|---|---|---|---|

| Unit | Hydrogen Preparation Unit | Nitrogen Preparation Unit | Compression Unit | Ammonia Synthesis Unit | Refrigeration Unit |

| Cooling Water (T/h) | 800 | 100 | 50 | 60 | 200 |

| Electricity Consumption (kWh/h) | 25,000 | 600 | 550 | 132 | 650 |

| Floor Area (m²) | 1,680 | 105 | 140 | 84 | 35 |

*Volume ratio of the layout:0.75| Demineralized water consumption of hydrogen production unit: 5T/h

*All data are only for theoretical reference, and the specific data shall be calculated according to the actual project background.

*All the data in the table are obtained with reference to theoretical data and actual project experience of KAPSOM, and are only for reference.

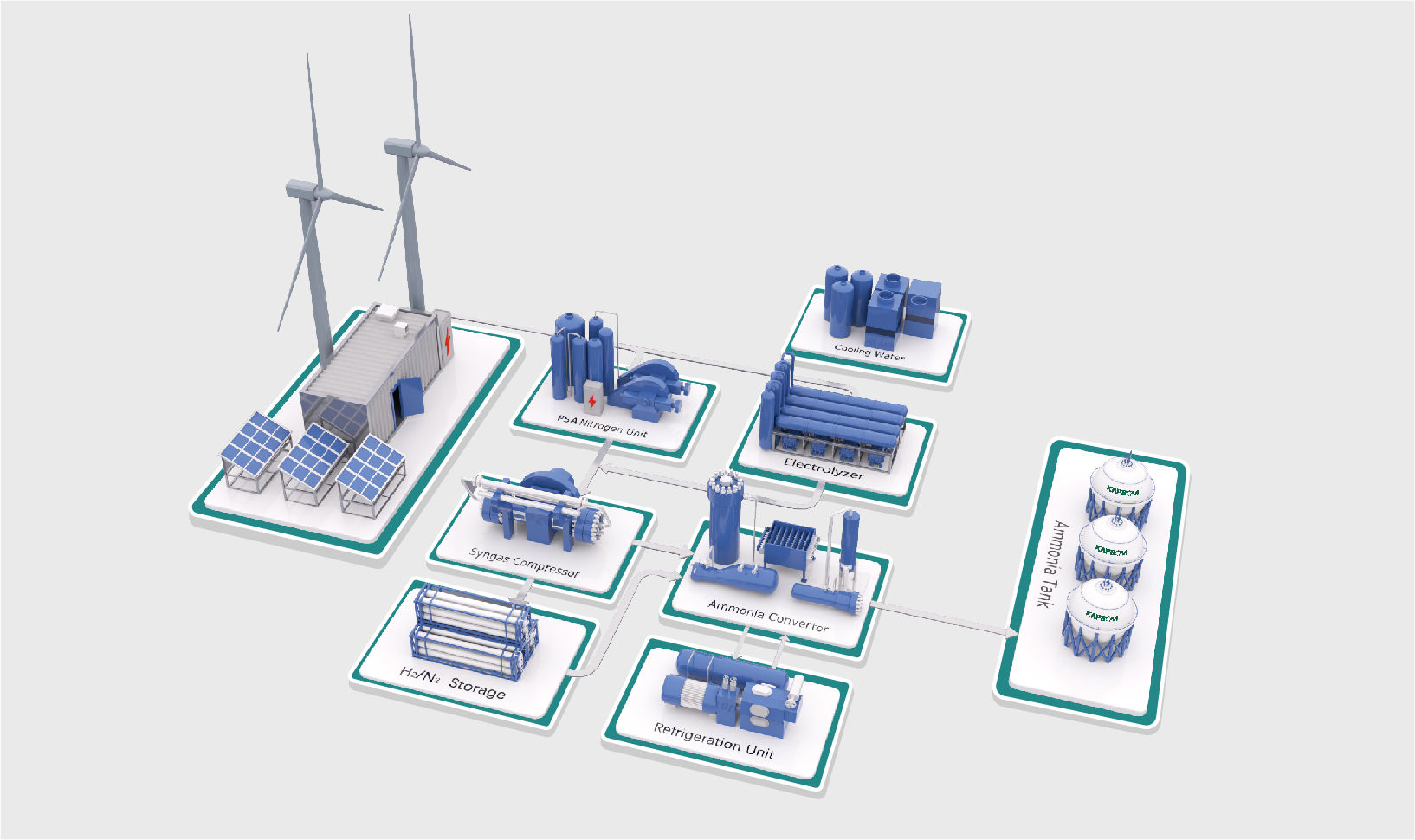

Green ammonia is ammonia produced using green hydrogen and 100% or a close to 100% renewable energy, with near-zero greenhouse gas emissions (less than or equal to 0.3 kg CO2e per kg of NH3 averaged over 12 months). This means that every step of the production process – including the separation of nitrogen from air, the production of hydrogen, and the synthesis of the two elements in the century-old Haber-B Bosch process – must be powered by renewable energy.

In 2021,KAPSOM helped a solar company in India build the world’s firstgreen ammonia plant, which can make them reduce CO2 emission by 6240TPA.Through the success operation of the project, it is not only a typical demonstration plant of power-to-x, but also lays the foundation for the customer’s second phase of large scalle green ammonia project.

In 2022, KAPSOM assisted a Saudi Arabian renewable energy company with the implementation of a green ammonia pllant ln order to facllitate equipment transportation, simplify on-site construction, and shorten commissioning and start-up, the project used the dimension of 40 GP container as the design basis for the ammonia synthesis unit for the first time, which is highly integrated.

In 2022, KAPSOM coopcrated with a Colombian venture capital company to explore the field of green ammonia locally. The owerall design of the project used containcrs as the basis to further improve the equipment integration of each main unit. At the same time a smart control system to realize automatic control was introduced into this project. It will save client 8,320 tons of carbon emissions per year.

In June 2023, KAPSOM cooperated with DGHV to help it build Africa’s first fully dynamic carbon-neutral green ammonia synthesis project. The total scale of the project is 1.5 GW. The first phase of the project received funding from the German Federal Ministry of Research and Education and the local government. The main purpose is to produce green hydrogen, green ammonia and their derivatives. This project lays the foundation for the commercial application of green ammonia in the following three and four phases.

Ammonia saved the world once; it might do it again.A century ago, the world faced a looming food crisis. A booming population was pushing farmers to grow crops faster than nitrogen-fixing bacteria in the soil could keep up, and the South American deposits of guano and natural nitrates they applied as fertilizer were dwindling.In what may still be the biggest global problem solved by chemistry, Fritz Haber and Carl Bosch developed a process to react hydrogen and atmospheric nitrogen under pressure to make ammonia, which farmers adopted in place of natural fertilizers.

Today’s crisis is climate change. This time, ammonia can be produced by hydrogen from water electrolysis and nitrogen separated from the air, the whole process is 100% carbon free. Compared with hydrogen, ammonia is expanding from the most traditional agricultural fertilizer field to the energy field due to its obvious advantages in storage and transportation.As a carrier of zero-carbon fuel and hydrogen energy, ammonia is an important pillar in achieving future green development.

Climate change poses a fundamental threat to the places, species and people’s livelihoods. To adequately address this crisis we must urgently reduce carbon pollution and prepare for the consequences of global warming.

One of the most promising applications of green ammonia is its utilization as a sustainable energy carrier. Ammonia can be produced from the available elemental hydrogen and nitrogen in the air and, if necessary, can be broken down again into its components with the help of an ammonia cracker. This means ammonia can be transported around the world from areas rich in wind and solar resources, where it can be used directly to generate electricity or cracked again into hydrogen for industrial applications.

Ammonia can also be burned directly, for example in gas turbines or ship engines. Due to its versatility, ammonia is an ideal green energy molecule. Ammonia has a higher energy density than hydrogen, which makes it easy to transport and easy to store. This makes green ammonia an ideal liquid energy carrier for transporting renewable energy “green hydrogen” over long distances.

Furthermore, ammonia is already a globally traded product with existing transportation infrastructure, thus offering significant potential for the global green energy economy and reduction of greenhouse gas emissions.

Green ammonia can be used as a medium for storing and transporting renewable energy. It’s especially useful for solar and wind energy, which are intermittent sources.

Green ammonia is particularly promising as a fuel for ships. The maritime industry, responsible for a significant portion of global emissions, is exploring ammonia as an alternative to heavy fuel oil. Ammonia-powered ships can operate with zero emissions, making it an attractive option for reducing the environmental impact of shipping.

Ammonia is a key ingredient in fertilizers. Green ammonia provides a more sustainable option for agriculture, reducing the carbon footprint of food production.

Green ammonia can be used to transport hydrogen, another clean fuel. Ammonia is easier to liquefy than hydrogen and requires less extreme conditions for storage and transport.

As a basic chemical, ammonia is used in the production of various products. Green ammonia offers a sustainable alternative for these processes.

Ammonia can be used in fuel cells to generate electricity. These fuel cells can power electric vehicles, offering a clean alternative to battery-powered electric vehicles, especially in heavy-duty and long-haul transportation where battery weight and charging time are limitations.