The ammonia cracking technology converts ammonia into hydrogen and nitrogen gas. Ammonia is a low-cost chemical raw material. It has the advantages of high energy density, easy compression and liquefaction, convenient storage and transportation, and does not produce CO2 when burned. Therefore, the idea of using ammonia as a hydrogen transport carrier has received widespread attention. Moreover, ammonia’s high mass and volumetric hydrogen storage densities make it a promising hydrogen transportation carrier.

ln addition, the nitrogen gas produced through ammonia catalytic cracking is an excellent protective gas and can be widely applied in the semiconductor and metallurgical industries.

| 100NM3/H AMMONIA CRACKING PLANT | |

|---|---|

| Capacity | 100 Nm3/h |

| Cracking Temperature | ~600℃ |

| Power | 1.5 kWh/Nm3 H2 |

| Ammonia consumption (kg/h NH3) | 76 kg/h |

| Forming gas production (Nm3/h N2;H2) | 200 Nm3/h |

| Hydrogen production (kg/h H2) | 8.93 kg/h |

| Conversion Rate | ≥99.7% |

| Operational flexibility | 30%~100% |

| 100NM3/H AMMONIA CRACKING PLANT | |

|---|---|

| Capacity | 150 Nm3/h |

| Cracking Temperature | ~600℃ |

| Power | 1.5 kWh/Nm3 H2 |

| Ammonia consumption (kg/h NH3) | 114 kg/h |

| Forming gas production (Nm3/h N2;H2) | 300 Nm3/h |

| Hydrogen production (kg/h H2) | 13.39 kg/h |

| Conversion Rate | ≥99.7% |

| Operational flexibility | 30%~100% |

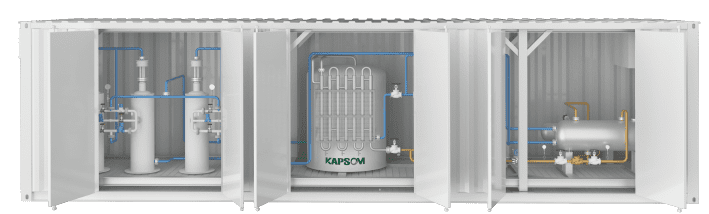

KAPSOM ammonia cracking unit can meet customer needs with excellent performance, flexibility and economy under low temperature conditions.

Green hydrogen boasts environmentally friendly characteristics. Nations engaged in hydrogen industry development account for 75% of the global economic output. However, due to the unresolved balance between hydrogen storage density, safety, and storage costs, the hydrogen industry has not yet formed a truly global supply chain and has not played a substantial role in driving global economic development and addressing climate change.

Ammonia cracking can help solve multiple challenges in hydrogen storage and transportation, reducing costs, and facilitating the formation of a global supply chain, paving the way for a true carbon-free future

Ammonia cracking is primarily employed for the production of hydrogen. Hydrogen is a versatile energy carrier and is widely used in industrial processes, such as hydrogenation reactions, ammonia synthesis, and in fuel cells for electricity generation.

The hydrogen generated from ammonia cracking can be used in various chemical synthesis processes, including the production of ammonia itself. It serves as a key raw material in the synthesis of various chemicals like methanol, fertilizers, and other industrial compounds.

Ammonia has been produced in large quantities for a long time, primarily for fertilizer production, which has led to the development of extensive storage and transportation infrastructure, thus reducing storage and transportation costs.

Hydrogen produced through ammonia cracking can be utilized in fuel cells to generate electricity. Fuel cells are electrochemical devices that convert hydrogen into electrical energy, with water and heat as byproducts.

Hydrogen obtained from ammonia cracking is often used in heat treatment processes, especially in industries like metallurgy. It can provide a reducing

atmosphere necessary for certain heat treatment applications.

Hydrogen is widely used in hydrogenation reactions, where it is added to various

compounds to reduce or saturate them. This is common in the production of edible oils, petrochemicals, and pharmaceuticals.

Hydrogen is a crucial element in various refinery processes, such as hydrocracking and desulfurization. These processes help refine crude oil into valuable products like gasoline and diesel.

Hydrogen is used in the electronics industry for processes like reducing oxides

during the production of semiconductors and other electronic components.

Hydrogen produced from ammonia cracking can be used as a fuel in combustion engines or gas turbines for power generation.

Ammonia cracking is a process that converts ammonia on a large scale into hydrogen gas. While green hydrogen is an abundant and versatile clean energy source, its properties, such as high volatility and low density, make hydrogen transportation challenging and costly. One economically viable method is to convert hydrogen gas into ammonia(NH3) for transportation, with subsequent release when needed. This release process can be achieved through ammonia cracking (decomposition) to produce hydrogen.

Efficient ammonia cracking technology is essential for achieving global decarbonization. By bridging gaps in the production chain, clean energy can be transported from regions with a surplus of renewable energy to areas with limited resources, facilitating the achievement of global green energy transition goals.

Currently, green hydrogen production still faces challenges such as high production costs, a lack of dedicated infrastructure, and significant energy losses during the production process. Among these, the electricity cost in the process of electrolytic hydrogen production accounts for 75% to 85% of the total cost, and the price of electricity directly determines the economic viability of green hydrogen.

Hydrogen is a clean fuel and energy carrier that plays a significant role in the future of sustainable energy. Hydrogen finds various applications as a raw material and fuel in the chemical industry. It is used in refining, ammonia production, methanol production, fertilizer production, food and pharmaceutical manufacturing, metal production, and low-carbon steel manufacturing. It is also used as fuel for fuel cell power generation and is poised to be a sustainable fuel for power generation in the construction and transportation sectors in the future.

Ammonia, as a hydrogen carrier, has garnered attention for its ability to safely transport and store hydrogen over long distances in large quantities. Ammonia cracking is a process that converts ammonia into hydrogen on a large scale, and it is an indispensable technology for extracting ammonia’s hydrogen component, playing a crucial role in building the hydrogen development supply chain. The development and commercialization of ammonia cracking systems will contribute to a sustainable, carbon-neutral world and usher in the era of large-scale hydrogen energy.