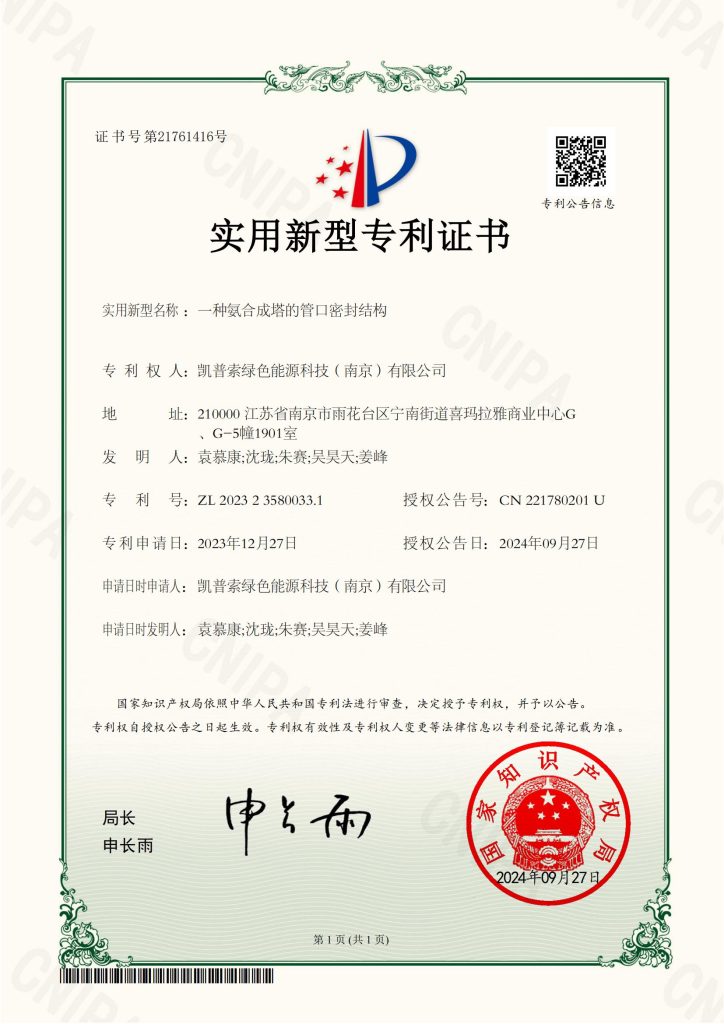

Recently, KAPSOM’s green energy technology R&D team has achieved another milestone with the successful authorization of their patent application for “A Sealing Structure for the Pipe Opening of an Ammonia Synthesis Tower” by the National Intellectual Property Administration. The patent number is ZL 2023 2 3580033.1.

In the context of “dual carbon” goals, green ammonia, as a “zero carbon” energy source, demonstrates significant advantages and provides new solutions for establishing a diversified clean energy supply system. Compared to traditional ammonia synthesis units, green ammonia synthesis equipment is typically smaller in size. However, the internal structure of the ammonia synthesis tower is complex, as the medium enters through various pipe openings and flows into different chambers, leading to suboptimal mixing. Moreover, the sealing structure for traditional ammonia synthesis pipe openings usually employs a flat cover welded to a flange on the upper surface, with sealing applied internally to the flange. This sealing method requires high technical skill from manufacturing personnel and involves multiple machined components, resulting in a complex structure and low material utilization. During maintenance, removing the top flat cover is time-consuming and may negatively impact production efficiency. Therefore, optimizing the sealing structure of the ammonia synthesis tower is crucial for enhancing production efficiency and economic benefits.

To address this technical challenge, the KAPSOM R&D team has designed a low-cost, highly reliable, and easy-to-maintain sealing structure for the ammonia synthesis tower pipe openings, effectively meeting production demands. This sealing structure consists of a flat cover and a flange, featuring vertically through-going mounting holes on the flat cover. The connecting pipe passes through these holes, and sealing material is filled in the gap between the connecting pipe and the inner wall of the mounting hole, achieving an effective sealing effect. This utility model enables effective sealing of the ammonia synthesis tower pipe openings without the need for welding, thus reducing manufacturing costs while enhancing reliability. During maintenance, only the flange needs to be removed to replace the sealing material, avoiding the cumbersome process of dismantling the entire flat cover, which effectively reduces maintenance intensity and costs.

In today’s rapidly advancing technological landscape, innovation has become the core driving force behind corporate development. As a leader in the green energy sector, KAPSOM is committed to technological innovation and product research and development, continuously providing high-quality solutions to our clients. Each patent reflects our dedication to innovation and quality.

For more information about KAPSOM and its initiatives, please contact dongling@kapsom.com.