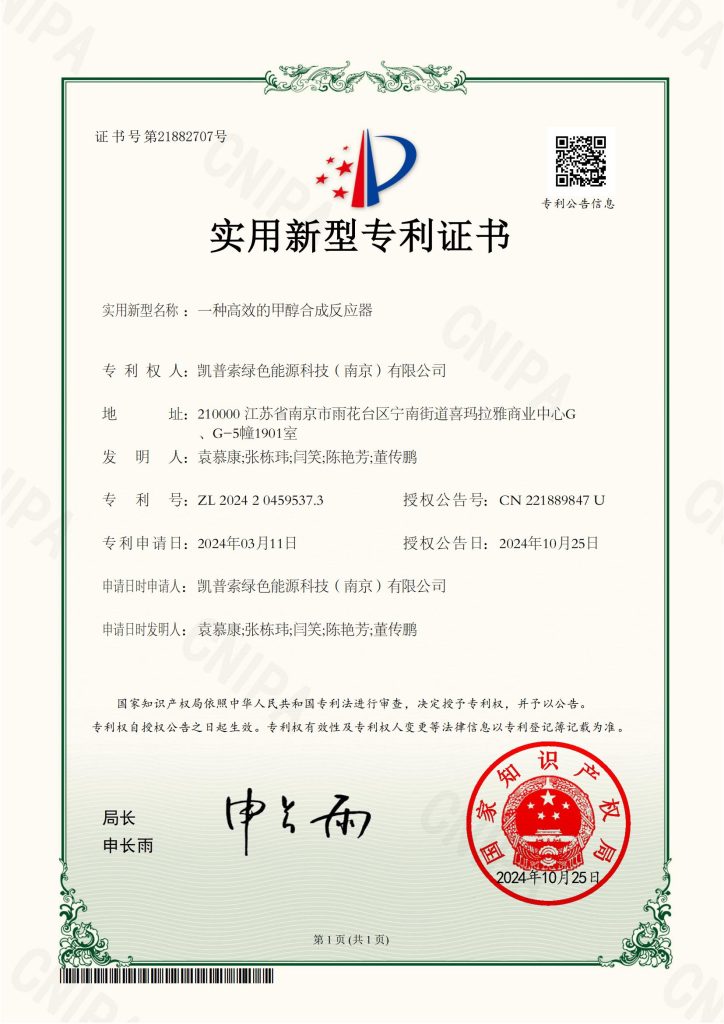

KAPSOM has recently been granted a Utility Model Patent by the Patent Examination Office of the China National Intellectual Property Administration (CNIPA). The patent, titled “A High-Efficiency Methanol Synthesis Reactor,” is registered under Patent No. ZL 2024 2 0459537.3. This achievement not only reaffirms the KAPSOM’s strong R&D capabilities but also marks another significant milestone in our commitment to technological innovation.

In the chemical industry, methanol is a fundamental raw material with wide-ranging applications. It plays a crucial role in various fields, including pharmaceuticals, organic synthesis, and coatings, serving as a key precursor for the synthesis of numerous chemical compounds. Moreover, synthetic methanol has become an essential component of the chemical industry due to its low production cost and diverse applications. Beyond its use in the production of alcohols, ethers, and acids, methanol also demonstrates significant potential in fuel cells and clean energy solutions, further expanding its importance in sustainable industrial development.

Currently, the axial-flow methanol synthesis reactors widely used in the market primarily adopt a shell-and-tube design, similar to a vertical shell-and-tube waste heat boiler, consisting of a shell and heat exchange tubes. However, these reactors face several technical challenges:

- Limited reaction efficiency: Due to the use of straight heat exchange tubes, the reaction gas flows at a high velocity, resulting in insufficient contact time with the catalyst. This leads to a 5%–15% reduction in reaction efficiency.

- Restricted heat exchange efficiency: The smooth inner and outer surfaces of the heat exchange tubes reduce the heat transfer rate between the reaction gas and the tubes. As a result, the actual heat exchange efficiency is approximately 12%–20% lower than the theoretical design.

To address the limitations of existing technology, KAPSOM R&D team has conducted extensive research and successfully developed a high-efficiency methanol synthesis reactor, achieving significant breakthroughs in three key areas:

- Innovative heat exchange tube design: The inner wall of the heat exchange tubes features an axially distributed corrugated structure, with a wave radius controlled between 1–5mm. This enhances the turbulence of the reaction gas, leading to improved reaction efficiency, with an overall efficiency increase of more than 10%.

- Optimized heat transfer performance: The outer wall of the heat exchange tubes is designed with threaded protrusions and a trapezoidal cross-section, increasing the contact area with the heat exchange medium inside the shell by approximately 15%–20%. This results in an 18% improvement in convective heat transfer efficiency.

- High-efficiency circulation system: Multiple inlet and outlet ports are strategically positioned at the top and bottom of the reactor, along with an integrated gas-liquid separator, forming a closed-loop circulation system that significantly enhances operational efficiency and stability.

The granting of this patent not only serves as a powerful endorsement of KAPSOM’s continuous innovation and high-quality development but also provides strong momentum for the advancement of the green energy sector. Looking ahead, KAPSOM will remain market-driven and innovation-led, continuously exploring new technologies, processes, and applications. With a steadfast commitment to technological advancement, KAPSOM will contribute its expertise and efforts to driving progress in green energy development.