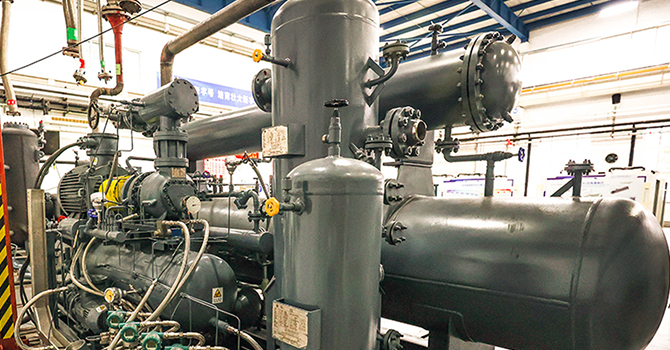

In November 2022, the main equipment of the 1,500TPY green ammonia plant to be sent to Saudi Arabia has been skid-mounted and installed at KAPSOM’s equipment manufacturing factory, including ammonia synthesis tower, soft water pre-heater, water cooler, cold exchanger, ammonia cooler, high pressure ammonia separator and so on. On 24th November, KAPSOM dispatched our equipment experts to Dalian to conduct final commissioning and acceptance of the ammonia compressor unit.

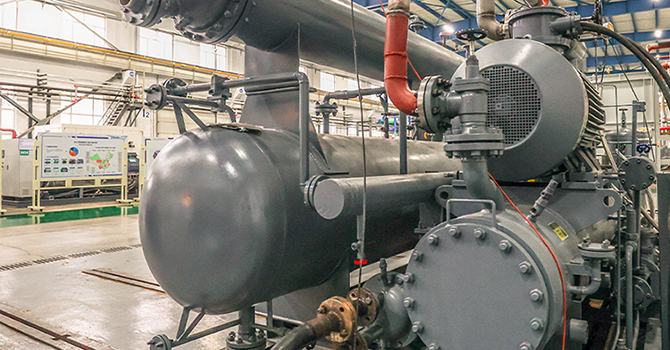

The main equipment of ammonia compressor unit includes compressor, compressor motor, oil separator, oil cooler, oil pump motor, horizontal condenser, liquid receiver, gas-liquid separator, oil collector and economizer. The ammonia compressor mainly uses ammonia (R717) as the cooling medium. It provides qualified cooling capacity for the ammonia synthesis device after compression, condensation, throttling and evaporation.

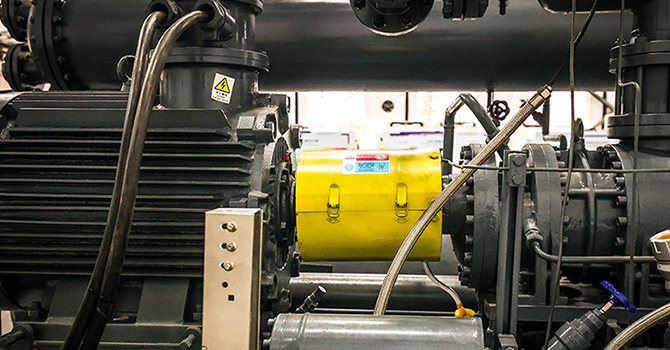

The ammonia compressor in this project is a screw compressor unit, and ammonia (R717) is used as the refrigerant. By compressing 0.1MPaG ammonia gas to 1.6MpaG liquid ammonia, the cooling capacity released from it will import the ammonia cooler at 17.3oC ammonia is cooled to -15oC and enters the high-pressure ammonia distributor.

KAPSOM always puts the interests of customers first and is committed to providing customers with high-quality equipment. The ammonia compressor we provide has fluctuation load of 30~110%, with designed service life of the core equipment more than 20 years and continuous operation time reaching over 8000 hours.